Plastic tube thickness measuring unit with automatic positioning system

Description

This plastic tube thickness measuring unit for extrusion line is

based on the principle of ultrasonic non-destructive measuring which

adopts the automatical capture and setting technology of ultrasonic

waves to do real time angle and orientation's adjustment algorithm, data

communication, field data collection, multiple control algorithm,

database access, etc. Thus provide perfect production testing method for

users who want to save the consumption of raw material and labor. And

efficiently reduce the accident of plastic pipe blow out caused by the

quality problems of tubular product.

Advantages

1. Our company develop automatic positioning system for this

plastic tube thickness measuring unit that can find out the unqualified

pipes after production and reduce the product quality risk. Besides the

positioning function, our equipment add the function of data collection

and database query. Thus the unqualified products can be found out after

the production and the longest product search time can trace back to

six months ago. More over, this technology makes our products have an

advantage over foreigner competitor and at the same time improve the

market share.

2. The sensitivity of ultrasonic wave processor combined with our

technology can realize all-round coverage of pipes and a measurement of

different speed tubes. The highest measurement of linear velocity can

reach to 100m/min.

3. This plastic tube thickness measuring unit is suitable for

measuring all kinds of material pipes (like PE, PVC, PERT, PP, etc) and

also can be used in the areas of all pipes (like gas pipe, the heating

pipe, drain-pipe, etc.).

Structure

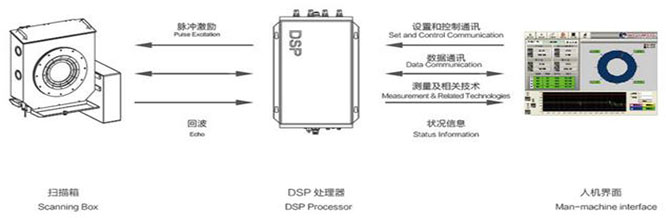

This plastic tube thickness measuring unit is composed of scanning

box, DSP signal processor, industrial personal computer and other

hardware structures.

Specifications

Probe: ULTRAMAC 1200-8T

Measurement range of external diameter: 800-1200mm